Product Description

Adhesive Heat Shrink Tube with Glue

Product Description

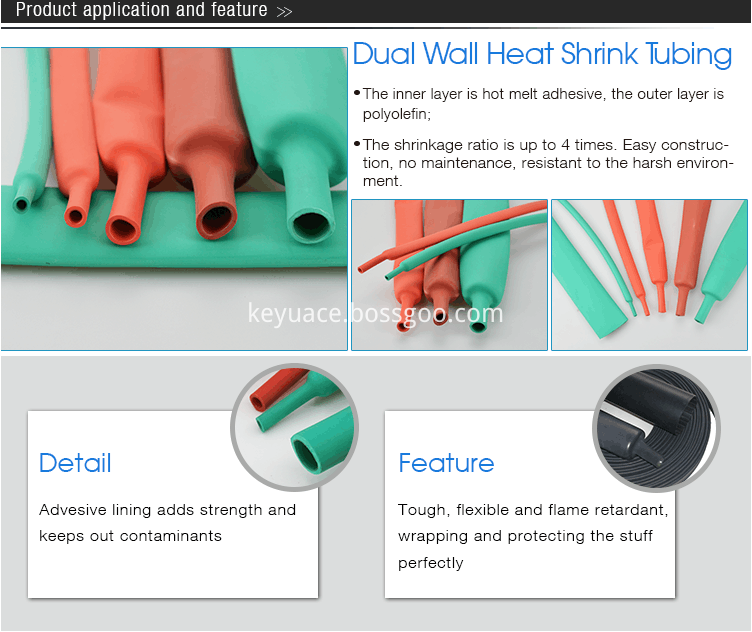

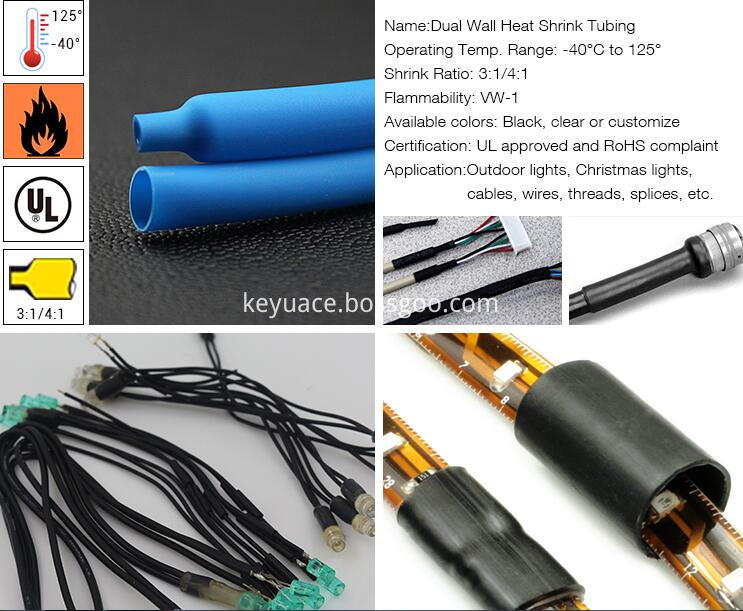

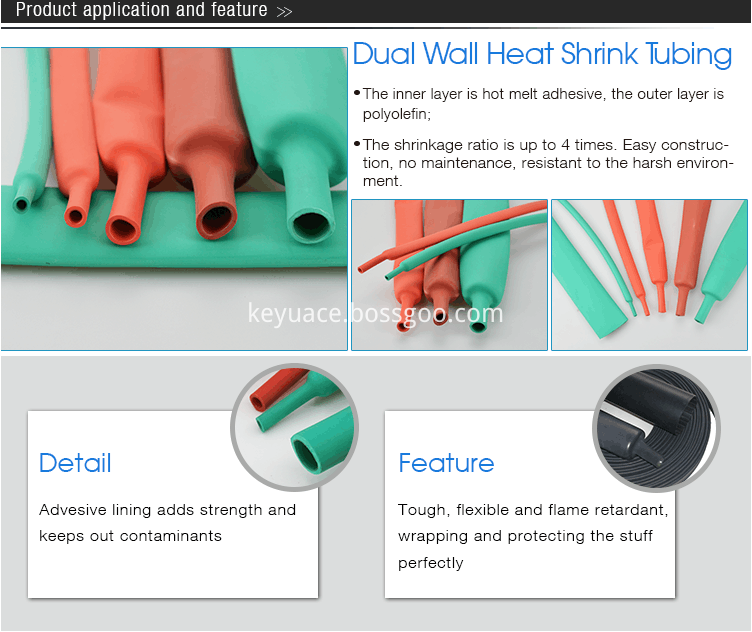

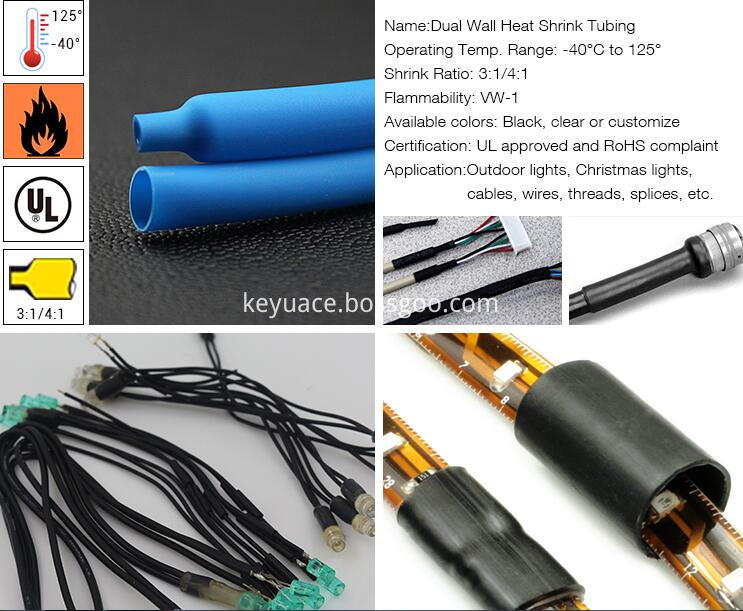

Adhesive Heat Shrink Tube with Glue(Waterproof Dual Wall Tubing )the outer layer makes by polyolefin PE material which is flame-resistant, semi-hard and wear-resistant. High shrink ratio, good adhesion performance, and the physical &chemical properties are also good. So it can protect the wire harness very well.

Adhesive Heat Shrink Tube(Polyolefin Dual Wall Tubing) the inner PA hot melt adhesive/or EVA hot melt adhesive :

High temperature resistance, waterproof, damp-proof, corrosion resistance.

Dual Wall Tubing apply to automobile wire harness, household wire harness, wire and cable branch, metal pipeline where need insulated protection.

Colorful Dual Wall Heat Shrink Tubing(waterproof heat shrink) is characterized by halogen free, Flame resistant.This kind of Heat Shrink Tube is environmentally friendly, soft, Insulation, shrink at low temperature. Voltage level of this heat shrink tube is 600V.

Features & Benefits

1, Semi-hard materials, flame resistance, abrasion resistance, anti-UV.

2, High shrink ratio: 4:1

3, Superior sealing, waterproof, dampproof, corrosion resistance.

Operating Indexes

1, First Shrink Temp.:70 degrees C

2, Final Shrink Temp.:125 degrees C

3, Working Temp.:-45~135 degrees C

Up to standard: Approvals

According with ROHS,135℃, 600V

Properties :

|

Product Properties

|

Test method

|

Test Date

|

|

Longitudinal shrink ratio

|

UL224

|

≥0~±5%

|

|

Tensile strength

|

ASTM D 2671

|

15MPa

|

|

Elongation at break

|

ASTM D 2671

|

≥400%

|

|

Tensile strength after aging

|

158℃,168hrs

|

≥13MPa

|

|

Elongation after aging

|

≥300%

|

|

Breakdown strength

|

IEC 93

|

≥20KV/mm

|

|

Corrosion

|

ASTM D 2671

|

Pass

|

|

Flammability

|

VW-1

|

Pass

|

|

Volume resistance

|

IEC 60093

|

≥1014Ω.cm(min.)

|

|

Hot melt adhesive technology index

|

|

water absorption

|

110 ± 5℃

|

ASTM E 28

|

|

Softening point

|

< 0.5%

|

ASTM D 570

|

|

peel strength (PE)

|

≥120N/25mm

|

ASTM D 1000

|

|

peel strength (AI)

|

≥80N/25mm

|

ASTM D 1000

|

Dimension :

|

Nominal Size

|

As supplied (mm)

|

After recovered ( mm )

|

Standard

Packing

(M/Roll)

|

|

(Inch)

|

(mm)

|

D :Inside

diameter

|

d :Inside diameter

|

T: Total wall thickness

|

t. : Adhesivel thickness

|

|

HUS-3X(3:1)

|

|

3/32

|

Φ2.4

|

≥2.4

|

≤0.80

|

0.80±0.30

|

0.40±0.20

|

200

|

|

1/8

|

Φ3.2

|

≥3.2

|

≤1.00

|

0.90±0.30

|

0.40±0.20

|

200

|

|

3/16

|

Φ4.8

|

≥4.8

|

≤1.60

|

1.05±0.30

|

0.40±0.20

|

100

|

|

1/4

|

Φ6.4

|

≥6.4

|

≤2.20

|

1.25±0.30

|

0.45±0.20

|

100

|

|

5/16

|

Φ7.9

|

≥7.9

|

≤2.70

|

1.35±0.30

|

0.45±0.20

|

100

|

|

3/8

|

Φ9.5

|

≥9.5

|

≤3.20

|

1.45±0.30

|

0.50±0.20

|

50

|

|

1/2

|

Φ12.7

|

≥12.7

|

≤4.20

|

1.65±0.30

|

0.50±0.20

|

1.22

|

|

5/8

|

Φ15.0

|

≥15.0

|

≤5.20

|

1.80±0.30

|

0.55±0.30

|

1.22

|

|

3/4

|

Φ19.1

|

≥19.1

|

≤6.30

|

1.95±0.30

|

0.60±0.30

|

1.22

|

|

1

|

Φ25.4

|

≥25.4

|

≤8.50

|

2.00±0.40

|

0.60±0.30

|

1.22

|

|

1-1/4

|

Φ30.0

|

≥30.0

|

≤10.20

|

2.15±0.40

|

0.65±0.30

|

1.22

|

|

1-1/2

|

Φ39.0

|

≥39.0

|

≤13.50

|

2.45±0.40

|

0.75±0.30

|

1.22

|

|

2

|

Φ50.0

|

≥50.0

|

≤17.00

|

2.75±0.40

|

0.80±0.30

|

1.22

|

|

2-1/2

|

Φ64.0

|

≥64.0

|

≤21.00

|

3.05±0.40

|

1.05±0.30

|

1.22

|

|

|

.png) Contact Now

Contact Now