Product Description

Anti Inductance Magnet Heat Shrink Tubing

Product description

KY-CX Magnet Heat Shrink Tubing uses high-quality high polymer and high-polymer alloy which is mixed by machine with scientific formula. after it molded, cross-link it by electronic accelerator and expand it continuously, finally make it. Magnetic heat shrink sleeve for inductance has not only the properties of protection, insulation, identification and others which belong to general heat shrink tubes, but also good electromagnetic compatibility which can improve the electromagnetic property and its stability. Low cost, stable property, easy to install, uniform shrinkage, widely use in electronic components’ industries.

Sensor Protection Tube Operation Indexes

1, Use Temp.: -55℃— 125℃;

2, Shrink Temp.: 100℃—125℃;

Up to standard: Approvals

Meet RoHs compliant

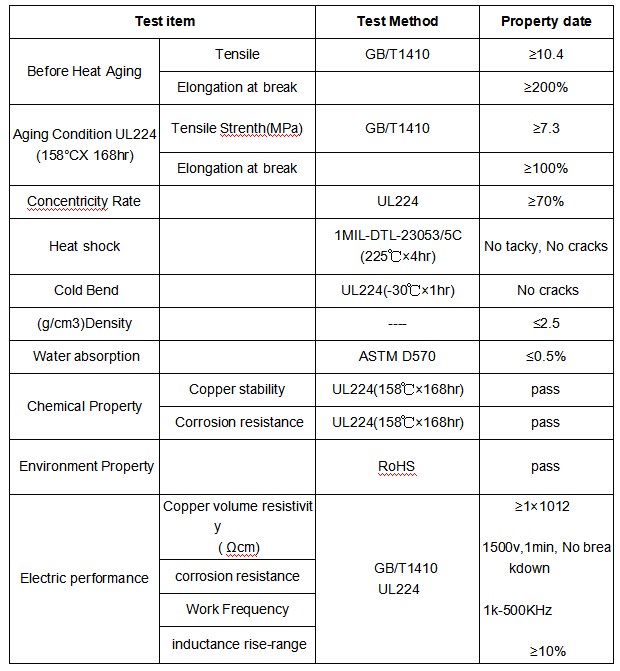

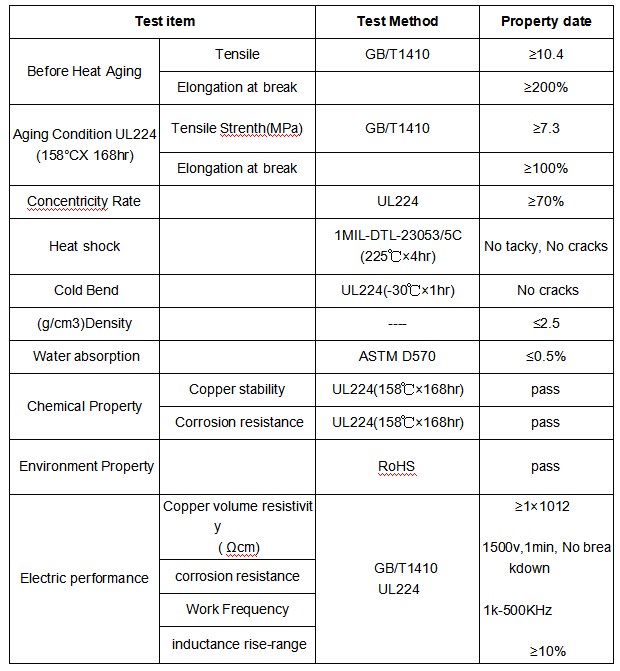

Technical Date

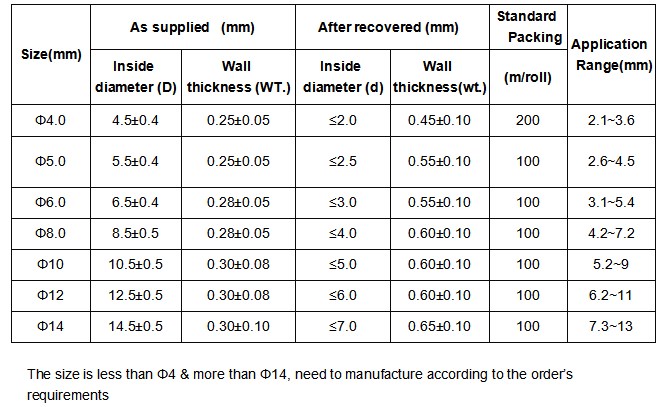

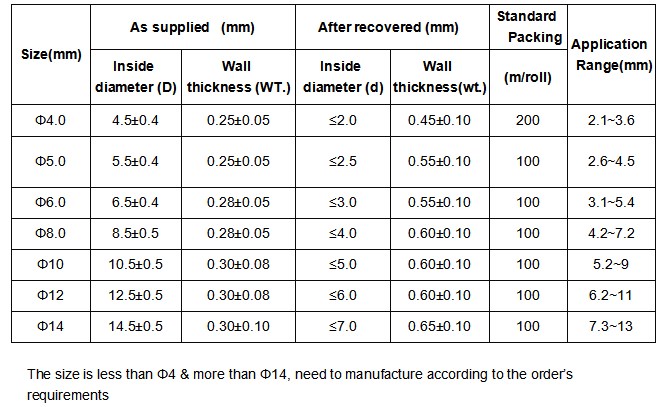

Dimension

.png) Contact Now

Contact Now