Product Description

High Performance Halogen Free Cable Label Marker

High Performance Halogen Free Cable Label Marker, Plastic Cable Markers are halogen free, environmentally friendly, Halogen Free Plastic Cable Label Marker, Flexible Cable Marker are made of cross-linked environmentally friendly polyolefin bombarded by high power electron beam with electronic accelerators to meet high end markets where highly reliable, economical and environmentally friendly cable& wire identification is required.

Cable marker heat shrink label sleeves, 1.5mm Cable Marker, 6.0mm Cable Marker accords to the requirements of UL224, CAN/CSA C22.2. Shrink ratios, both 2:1 and 3:1 are available. See the below tables.

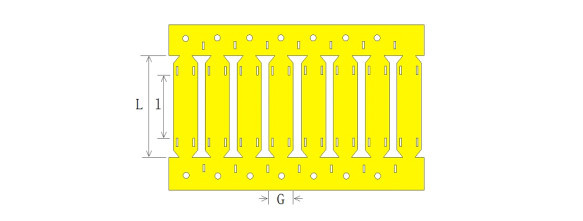

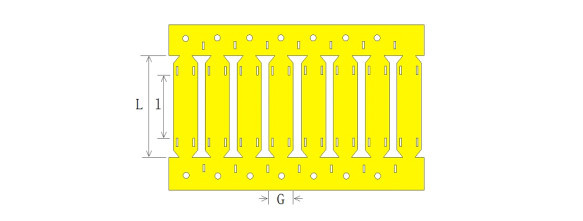

Cable Marker For Electric Wire 1.5mm - 6.0mm (size can be customized)

Product Application

Bundle the cables and wire harnesses by way of binding wire, as the identification of large-diameter cables, splice of wire harnesses and wire line route.

Features:

² Halogen free materials, ideal for identifying purposes in electronics/electrical power, communications, architectural industries

² Not necessary to disconnect the electrical return circuit when installing, dismantling, or maintenance

² Using standard cable ties, no extra work required, easy to handle

² Temperature resistance, rated temperature, 125°C

² High flame resistance, VW-1

² RoHS compliant, meets SONY SS-00259

² Permanent identification, not melting in high temp, not turning fragile in low temp, resistant to scrape, rub, abrasion

² Computer-printable, any character and logo are easy to design.

² Rated Temperature:

Material Standard: UL224, CAN/CSA C22.2

Color Code Soundness: SAE-AS 81531and MIL-STD-202F/215J

² Standards:

Material standards: ASTM D 2671/DIN5510-2

British/French smoke toxicity standards: BS 6853/NF F 16-101

Color code soundness: SAE-AS 81531 and MIL-STD-202G/215K

Application Fields

1, Military projects, steamship, submarine, guided missile and other manufacturing industries: identification for the installation, repair and grouped splices of electrical circuit.

2, Train, aircraft, automobile and other manufacturing industries: identification for the installation, repair and grouped splices of electrical circuit.

3, Metro, ballet train tunnel engineering: identification for the construction, installation, repair and grouped splices of electrical circuit.

4, Chemical plant pipeline identification: Identification for the water gas, hydrogen and nitrogen pipeline of petrochemical enterprise, synthetic ammonia factory, urea plant, etc.

5, Identification for the whereabouts and splices of the banking financial institution information management system banking financial institution information management system wire line.

6, Identification for the whereabouts and butt joints of optical fiber and cable, junction box, adapter junction box and communication circuits.

7, Identification for electrical circuit of manufacturer, central control room, hidden power cable in plant, information circuit layout and splices

8, Identification for electrical circuits, water pipes and gas pipes of high-rise building and community residence, whereabouts and splices of power cable, telephone wire and internet cable .

Related product instruction

1, Printed content : customized.

2, Cable marker inner diameter size: 2.0~3.0, Other size is available to customize.

3, Cable marker length range: Customized, shrink ratio: 3:1 ,2:1.

4, Machine automatically half-cut, keep connection among different cable marker, convenient to peel off

5, Environment, flame-resistant, insulated, temperature-resistant

6, PVC blank sleeve: oil-resistant, aging-resistant, acid-resistant, not easy to fade, good insulation capacity.

Environment certification:

Heat shrinkable identification tube and PVC sleeve accord with EU RoHs compliant.

Product size:

The max. Size can be up to 60 mm

Remark:

Our company heat shrinkable identification sleeve, cable marker:

1, Same font, same font size.

2, Ensure the printing doesn`t fade.

|

Performance

|

Indicators

|

Test Method

|

|

Typical properties

|

Unit

|

States

|

|

Tensile Strength

|

Mpa

|

Unaged

|

≥10.3

|

ASTM G 154,MIL-DTL-23053E

ISO 37,500mm/min

175°C,168h,ISO 188

|

|

Heat aged/ After fluids/UV aged

|

≥6.9

|

|

Elongation at break

|

%

|

Unaged

|

≥200

|

|

Heat aged/ After fluid

|

≥100

|

|

Secant Modulus

|

Mpa

|

Unaged

|

<173

|

ASTM D 882

|

|

Voltage Withstand

|

V

|

Unaged / After aged

|

2500V, No breakdown in 60 sec.

|

IEC 243,ASTM G 154

175°C,168h,ISO 188

|

|

Dielectric Strength

|

MV/m

|

Before aged

|

≥19.7

|

|

Heat aged/ After fluid/ UV aged

|

≥15.8

|

|

Volume Resistivity

|

Ω.cm

|

Unaged

|

≥1014

|

IEC 93

|

|

Dielectric constant

|

-

|

Unaged

|

-

|

ASTM 150

|

|

Water Absorption

|

-

|

Unaged

|

≤1.0

|

ASTM 570,23°C,24h

|

|

Bare Copper Corrosion

|

-

|

Unaged

|

No corrosion

|

23°C,Rh 95±5%,24h

175°C,16h

|

|

Heat Shock

|

-

|

Unaged

|

No cracks, flowing, dripping

|

Wind to the specified mandrel,225°C,4h

|

|

Cold Flexibility

|

-

|

Unaged

|

No cracks

|

Wind to the specified mandrel, -30°C, 1h

|

|

Flammability

|

-

|

Unaged

|

VW-1

|

IEC 60332-1-3 Ed.1.0 b:2004

|

|

Longitudinal Change

|

%

|

Unaged

|

2X: -10~+1

|

200°C,Constant 3min

|

|

3X: -15~+5

|

|

Smoke Density

|

-

|

Unaged

|

-

|

DIN 5510-2

|

|

Toxcity Index

|

-

|

Unaged

|

-

|

BS 6853:1999

|

|

Size

(inch)

|

Inside diameter

|

Recommended use range(MM/INCH)

|

|

As supplied (min.)

|

After recovery (max.)

|

|

3/32

|

2.4 (0.093)

|

0.8 (0.031)

|

0.9-2.0 (0.035-0.079)

|

|

1/8

|

3.2 (0.125)

|

1.0 (0.042)

|

1.1-2.7 (0.044-0.105)

|

|

3/16

|

4.8 (0.187)

|

1.6 (0.062)

|

1.8-4.1 (0.069-0.160)

|

|

1/4

|

6.4 (0.250)

|

2.1 (0.083)

|

2.3-5.5 (0.091-0.215)

|

|

3/8

|

9.5 (0.375)

|

|

.png) Contact Now

Contact Now