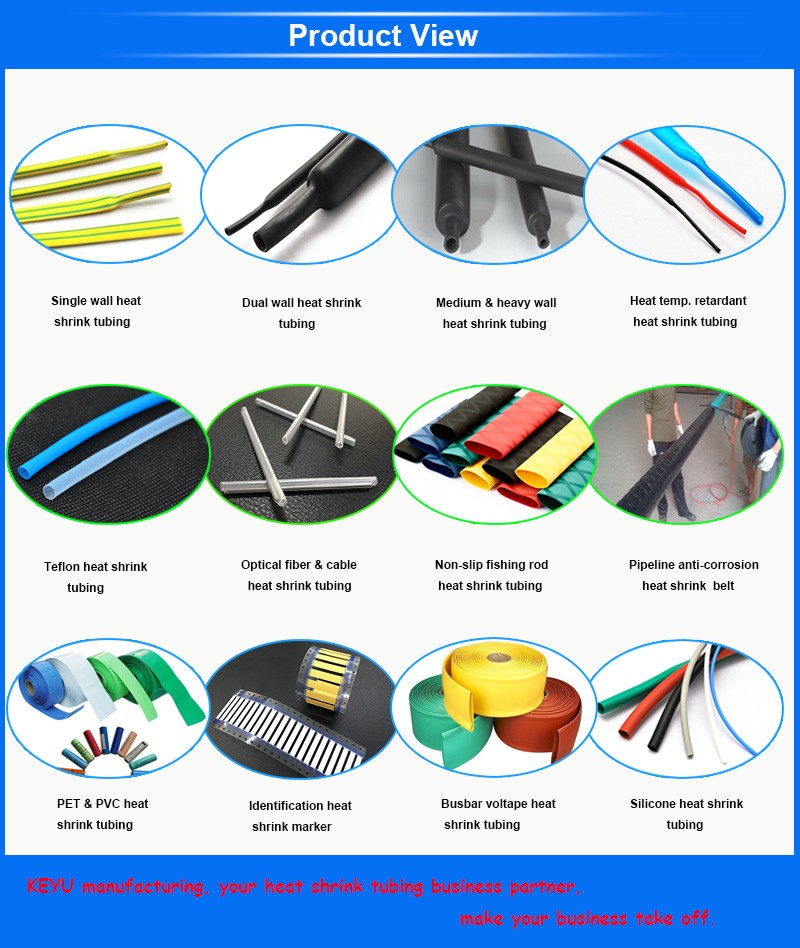

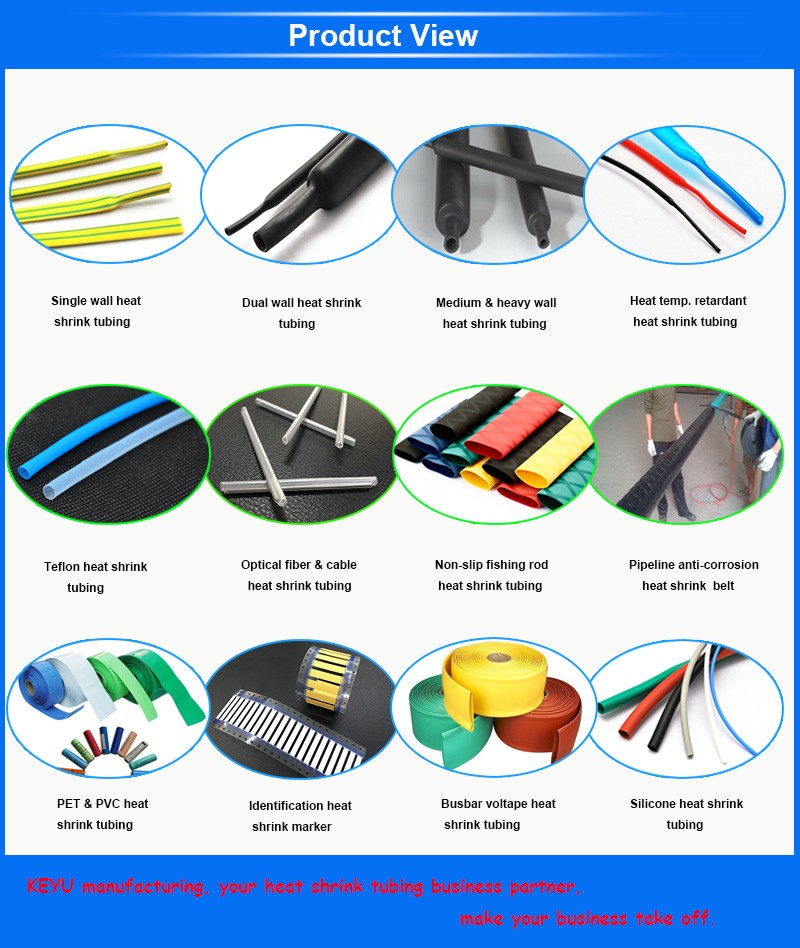

Product Description

Halogen Free Flame retardant Heat Shrink Tube

Dual Wall Tubing , Waterproof Dual Wall Tubing is made of outer halogen free flame-resistant insulated polyolefin PE material layer and the inner transparent EVA hot melt adhesive layer. Waterproof, anti-corrosion, good buffer against mechanical strain and superior sealing capacity. Wire Shrink Tube,Cable Heat Shrink , Polyolefin Dual Wall Tubing, Dual Walled Electrical Heat Shrink Tubing widely used in all kinds of wire harness, marine wire, cable, electronic components and others where need sealing and waterproof.

Dual Wall Heat Shrink Tubing typical applications include environmental sealing of in-line splices, sealing and strain relief of connectors and terminals, abrasion protection and electrical insulation of automotive wiring harness splices and valuable components, fleet & marine sealing & protection.

Features & Benefits:

1, Flame-resistant, anti-UV

2, Heat Shrink Ratio: 3:1

3, Water proof, anti-corrosion, damp-proof

Operating indexes:

1,First shrink temp.: 70 degrees C

2,Final shrink temp.: 125 degrees C

3,Operating temp.: -45 degrees C~125 degrees C

Up to standard: approvals

Meet RoHs, 125 degrees C, 600V

|

Product Properties

|

Test Method

|

Test Date

|

|

Longitudinal shrinkage

|

ASTM D 2671

|

-8%~+8%

|

|

Tensile strength

|

ASTM D 2671

|

≥10.5MPa

|

|

Elongation at break

|

ASTM D 2671

|

≥300%

|

|

Tensile strength after aging

|

175℃,168hrs

|

≥8.5MPa

|

|

Elongation after aging

|

≥100%

|

|

Heat shock

|

ASTM D 2671

250℃,4hrs

|

PASS

|

|

Cold bend (-30℃, 1hrs)

|

ASTM D 2671

-45℃,4 hrs

|

No break

|

|

Breakdown strength

|

IEC 60243

|

≥15KV/mm

|

|

Corrosion

|

ASTM D 2671

|

Pass

|

|

Flammability

|

AMS-DTL-2305/5

|

Self-extinguish in 30 seconds

|

|

Volume resistance

|

IEC 60093

|

≥1014Ω.cm(min.)

|

|

Hot melt adhesive technology index

|

|

water absorption

|

95 ± 5℃

|

ASTM E 28

|

|

Softening point

|

< 0.5%

|

ASTM D 570

|

|

peel strength (PE)

|

≥120N/25mm

|

ASTM D 1000

|

|

peel strength (AI)

|

≥80N/25mm

|

ASTM D 1000

|

|

Nominal Size

|

As supplied

(mm)

|

After recovered ( mm )

|

Standard Packing

(M/Roll)

|

|

(mm)

|

(inch)

|

D min.)

Inside diameter

|

d(min.)

Inside diameter

|

Wall Total thickness WT

|

t. Adhesivel thickness

|

|

HUS-W, 3X

|

|

¢ 2.4

|

3/32

|

≥2.4

|

≤0.80

|

0.85 ± 0.15

|

0.35 ± 0.08

|

200

|

|

¢ 3.2

|

1/8

|

≥3.2

|

≤1.00

|

0.95 ± 0.15

|

0.35 ± 0.08

|

200

|

|

¢ 4.8

|

3/16

|

≥4.8

|

≤1.60

|

1.10 ± 0.15

|

0.40 ± 0.08

|

100

|

|

¢ 6.4

|

1/4

|

≥6.4

|

≤2.20

|

1.20 ± 0.15

|

0.45 ± 0.08

|

100

|

|

¢ 7.9

|

5/16

|

≥7.9

|

≤2.70

|

1.35 ± 0.15

|

0.50 ± 0.08

|

100

|

|

¢ 9.5

|

3/8

|

≥9.5

|

≤3.20

|

1.45 ± 0.15

|

0.50 ± 0.08

|

50

|

|

¢ 12.7

|

1/2

|

≥12.7

|

≤4.20

|

1.70 ± 0.15

|

0.50 ± 0.08

|

1.22

|

|

¢ 15.0

|

5/8

|

≥15.0

|

≤5.20

|

1.80 ± 0.15

|

0.55 ± 0.10

|

1.22

|

|

¢ 19.1

|

3/4

|

≥19.1

|

≤6.30

|

2.00 ± 0.20

|

0.55 ± 0.10

|

1.22

|

|

¢ 25.4

|

1

|

≥25.4

|

≤8.50

|

2.10 ± 0.20

|

0.55 ± 0.10

|

1.22

|

|

¢ 30.0

|

1-1/4

|

≥30.0

|

≤10.20

|

2.20 ± 0.2.0

|

0.60 ± 0.10

|

1.22

|

|

¢ 39.0

|

1-1/2

|

≥39.0

|

≤13.50

|

2.40 ± 0.20

|

0.60 ± 0.10

|

1.22

|

|

¢ 50.0

|

2

|

≥50.0

|

≤17.00

|

2.70 ± 0.20

|

0.80 ± 0.10

|

1.22

|

Standard color: Black (Other international colors can be customized)

Pointed size: can be customized according to customers' requests.

.png) Contact Now

Contact Now